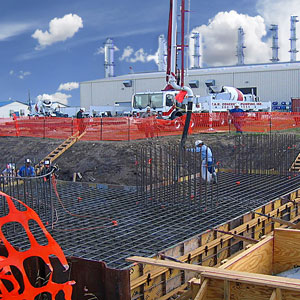

As a full-service general industrial contractor, Performance Contractors executes a significant amount of civil projects in varying industries each year. Performance Contractors pours in excess of 125,000 cubic yards of concrete each year with our direct hire personnel.

A large number of direct hire resources make up this very valuable resource at Performance Contractors. High alloy welding is a daily requirement in our pipe fabrication facilities as well as in the field. Properly certified welders execute this work per acceptable welding procedures developed by our Quality Assurance and Control Department.

The success of Performance Contractors’ construction projects relies upon our ability to effectively control project delivery requirements. Now operating four fabrication facilities in 250,000 square feet of shop space along with pipe support fabrication allows for peak performance management through timely and cost effective delivery of fabrication pipe.

Fabrication and assembly of modular units is done at offsite modular construction yards at the plant site. Experience includes fabrication and shipment fabrication and installation. Modules are built and shipped worldwide from one of our modular yards in Louisiana and Alabama. Numerous projects have been executed via modular units that are built and erected by Performance forces.

“R”, “S” and “U” Code Stamps are maintained for coded vessel fabrication as well as field repairs.

Facility dismantling and shipment for erection at new locations is a superior service at Performance Contractors.

Supplemental resources are provided for maintenance, turnarounds and capital projects.

Resident maintenance contracts make up a very important aspect of our business. Flexible manpower levels working in a “productive, lump sum” culture are Performance Contractors’ maintenance trademarks.

Timely mobilization of of company supervision and craft labor are vital to supporting unplanned plant outages. Performance Contractors is perfectly situated to support unplanned shutdowns with current company resources as we control where our craft personnel report on a daily basis.

Company owned bundle extraction equipment offers cost effective support to turnaround and client specific requirements. Performance Contractors owns and operates the following bundle extraction equipment:

Types: Aerial and truck mounted

Fabricator: Peinemann

Company owned bundle extraction equipment offers cost effective support to turnaround and client specific requirements. Performance Contractors owns and operates the following bundle extraction equipment:

Types: Aerial and truck mounted

Fabricator: Peinemann

We routinely partner with engineering companies to bid and execute contracts via the engineering procurement and construction format.

Performance Contractors expends 2.5 million direct man hours annually in the execution of turnarounds and outages. Our company is perfectly suited to support turnarounds as we manage the utilization of our manpower daily, thus enabling us to keep our most valued resources consistently employed as we move them from one location to the next. Performance personnel excel from the construction and planning stages through plant start-up and commissioning.